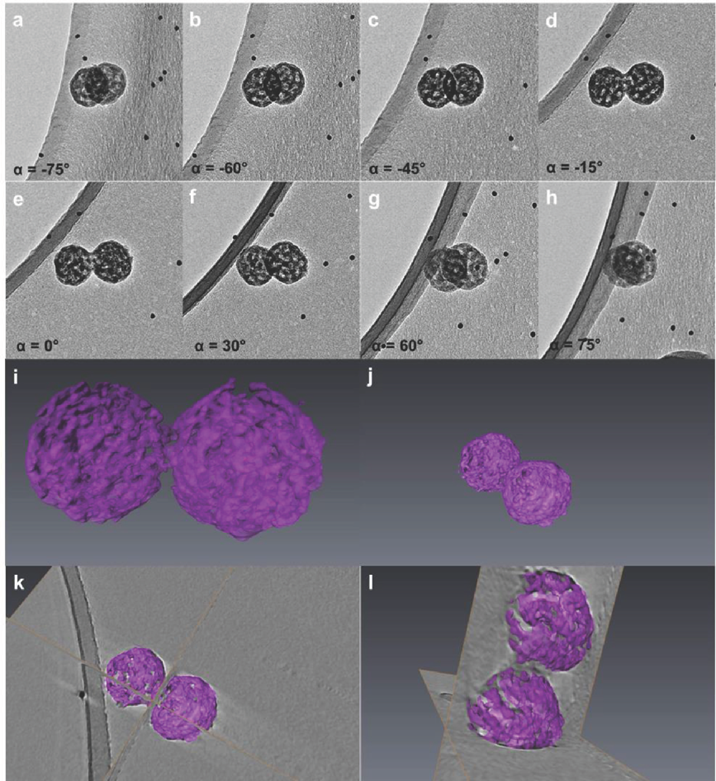

Calcination of hydrated iron salts in the pores of both spherical and rod-shaped mesoporous silica nanoparticles (NPs) changes the internal structure from an ordered 2D hexagonal structure into a smaller number of large voids in the particles with sizes ranging from large hollow cores down to ten nanometer voids. The voids only form when the heating rate is rapid at a rate of 30 °C min−1. The sizes of the voids are controlled reproducibly by the final calcination temperature; as the temperature is decreased the number of voids decreases as their size increases. The phase of the iron oxide NPs is α-Fe2O3 when annealed at 500 °C, and Fe3O4 when annealed at lower temperatures. The water molecules in the hydrated iron (III) chloride precursor salts appear to play important roles by hydrolyzing Si[BOND]O[BOND]Si bonding, and the resulting silanol is mobile enough to affect the reconstruction into the framed hollow structures at high temperature. Along with hexahydrates, trivalent Fe3+ ions are assumed to contribute to the structure disruption of mesoporous silica by replacing tetrahedral Si4+ ions and making Fe[BOND]O[BOND]Si bonding. Volume fraction tomography images generated from transmission electron microscopy (TEM) images enable precise visualization of the structures. These results provide a controllable method of engineering the internal shapes in silica matrices containing superparamagnetic NPs.